In process industries, monitoring the flow of liquids or gases is critical for efficient equipment functioning and ensuring product quality. This is where industrial sight glass flow indicators play a crucial role. These devices allow operators to visually observe the flow of fluids through pipelines, tanks, and vessels. This article will discuss industrial Custom Glass flow indicators, their types, applications, and benefits.

Introduction

In many process industries, accurate and reliable fluid flow monitoring is crucial for proper functioning equipment, ensuring product quality, and reducing operational costs. Industrial Custom Glass flow indicators provide operators with a clear view of the flow of liquids or gases through pipes, tanks, and vessels. These devices can be installed in various applications, from chemical processing to food and beverage production.

What is an Industrial Sight Glass Flow Indicator?

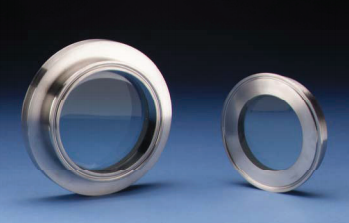

An industrial sight glass flow indicator is a transparent device that allows operators to visually monitor the flow of fluids through pipelines, tanks, and vessels. These devices typically consist of a glass or plastic window and a housing attached to the channel or tank. The accommodation is design to withstand the pressure and temperature of the fluid being monitored.

Types of Industrial Sight Glass Flow Indicators

Several types of industrial Custom Glass flow indicators are available in the market, each with unique features and benefits.

a. Flapper Type Sight Glass Flow Indicator

A flapper-type Custom Glassflow indicator is a device that uses a hinged flapper to indicate the flow of fluids. When the liquid is flowing, the flapper moves, indicating the direction and speed of the flow.

b. Rotating Paddle Type Sight Glass Flow Indicator

A rotating paddle-type Custom Glass flow indicator is a device that uses a paddle to indicate the flow of fluids. The paddle is connected to a shaft that rotates when the liquid flows, visually displaying the flow rate.

c. Sight Glass Level Gauge

A sight glass level gauge is a device that allows operators to monitor the level of fluids in a tank or vessel. These devices typically have a transparent tube or window attached to the tank or vessel. The fluid level can be visually observe through the line or window.

Applications of Industrial Sight Glass Flow Indicators

Industrial Custom Glass flow indicators are use in a variety of applications, including:

Chemical processing

Food and beverage production

Pharmaceutical manufacturing

Oil and gas production

Water and wastewater treatment

Power generation

Benefits of Industrial Sight Glass Flow Indicators

There are several benefits of using industrial Custom Glass flow indicators in process industries, including:

Improved process efficiency: By monitoring the flow of fluids, operators can identify and address any issues that may be affecting the efficiency of the process.

Increased product quality: By ensuring that the correct amount of fluid flows through the system, industrial sight glass flow indicators can help improve the quality of the end product.

Reduced downtime: By providing operators with a clear view of the flow of fluids,

Factors to Consider When Selecting Industrial Sight Glass Flow Indicators

When selecting an industrial Custom Glass flow indicator, there are several factors to consider, including:

Pressure and temperature ratings: The flow indicator must withstand the pressure and temperature of the fluid being monitored.

Material of construction: The flow indicator must be made of a material compatible with the monitored fluid.

Flow rate: The flow indicator must be able to measure the flow rate of the fluid accurately.

Visibility: The flow indicator must provide a clear view of the fluid flow, even under difficult lighting conditions.

Installation and Maintenance of Industrial Sight Glass Flow Indicators

Proper installation and maintenance of industrial Custom Glass flow indicators are essential to ensure reliable operation. The following are some tips for installation and maintenance:

Ensure that the flow indicator is installe in the correct orientation.

Regularly inspect the flow indicator for any signs of damage or wear.

Clean the flow indicator regularly to ensure that it provides a clear view of the fluid flow.

Replace any damaged or worn components promptly.

Industrial Sight Glass Flow Indicators in Custom Glass Applications

Industrial sight glass flow indicators can also be used in custom glass applications. Custom glass flow indicators can be designed to meet specific requirements, including:

Custom sizes and shapes

Materials for construction

Custom pressure and temperature ratings

Sight flow indicators can be useing in a variety of applications, including:

Biopharmaceutical manufacturing

Semiconductor manufacturing

Aerospace and defense

Scientific research

Industrial Sight Glass Flow Indicators: A Cost-Effective Solution

Industrial sight glass flow indicators are a cost-effective solution for monitoring the flow of fluids in process industries. Compared to other flow monitoring technologies, such as flow meters, industrial Custom Glass flow indicators are less expensive and easier to install and maintain.

Conclusion

In conclusion, industrial sight glass flow indicators are essential for process industries, providing operators with a clear view of the flow of fluids through pipelines, tanks, and vessels. These devices are available in various types and can be use in multiple applications, from chemical processing to scientific research. When selecting and installing industrial Custom Glass flow indicators, it is essential to consider factors such as pressure and temperature ratings, the material of construction, and visibility. With proper installation and maintenance, industrial sight glass flow indicators can provide reliable and cost-effective monitoring of fluid flow.

Read More About : Borosilicate Glass